The mist cooling system utilizes the principle of evaporative cooling, where water vapor absorbs heat, thereby achieving a cooling effect. The higher the temperature and the lower the relative humidity, the greater the cooling potential of misting technology. It is important to note that mist cooling systems have been widely applied. In the scorching summer, when the existing outdoor heat environment cannot meet human comfort needs, the mist cooling system becomes particularly significant as a focal point for improving comfort levels

Dry environments benefit more from cooling effects than humid ones. Due to the increase in indoor relative humidity, traditional residential buildings usually do not use cooling systems. However, some well-known buildings still use mist cooling methods, including livestock sheds, greenhouses, and outdoor structures. In these unique environments, proper air temperature and humidity are two key environmental parameters for the healthy growth of livestock, poultry, and plants.

Harsh high-temperature environments can lead to poor insulation performance and poor sealing in livestock and poultry sheds, causing a sharp decline in survival rates. Since traditional air conditioning consumes high energy, mist cooling systems have become an effective means of improving the thermal environment inside livestock and poultry sheds. These systems offer a feasible solution for reducing heat stress and enhancing the welfare of animals and plants in various agricultural environments.

How Do Misting Cooling Systems Improve Hot Environments?

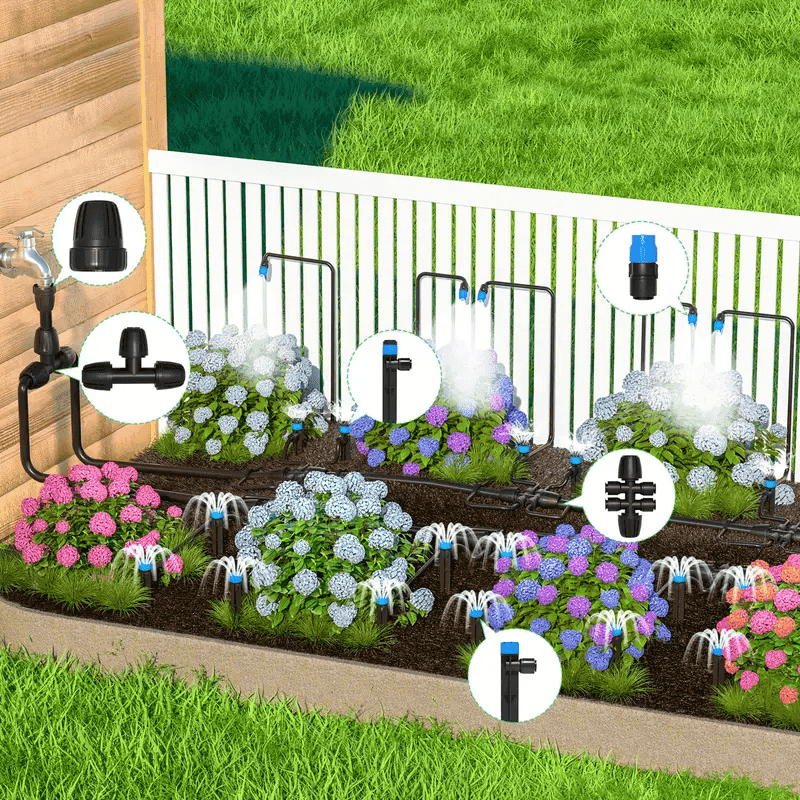

Misting cooling systems have emerged as an innovative solution to enhance thermal comfort in urban public spaces. Through a series of carefully designed experiments, these systems have demonstrated their strong ability to improve the microclimate. Below is an introduction to how these systems work and their impact based on proven case studies:

Working Principle

Misting cooling systems rely on evaporative cooling. These systems disperse fine mist into the air. As the water droplets evaporate, they absorb heat from the air, thereby lowering the ambient temperature. This principle takes advantage of latent heat of evaporation, effectively cooling the surrounding area.

Solar Energy and Fuzzy Logic Control: Modern misting systems integrate solar energy and fuzzy logic for smarter energy usage and operational efficiency. Solar panels provide renewable energy to the system, while fuzzy logic controllers optimize mist release based on humidity, temperature, and solar intensity, reducing water and energy consumption.

Case Studies

-

School Rooftops: After installing misting nozzles on a school rooftop for a week, temperatures at 2.2m and 1.1m heights dropped significantly by 7.4°C, with relative humidity controlled to below a 13% increase. This application highlights the system’s ability to create more comfortable outdoor learning environments.

-

Residential Areas: In residential areas, the system can effectively lower temperatures by 3°C within a 3-meter mist radius, especially when wind speeds are below 3.3 meters per second. This demonstrates the system’s practicality in private settings, enhancing comfort during hot weather.

-

Air Conditioning Efficiency: By installing misting systems around rooftop and balcony air conditioning units, temperatures can be reduced by up to 60%, and energy consumption can be cut by up to 80%. This not only improves the efficiency of air conditioning units by reducing their cooling load but also significantly saves energy.

-

Roof Cooling: Analysis of the relationship between environmental parameters and cooling effects showed that external surface temperatures can be reduced by 4.8 to 19.5°C, while internal temperatures can be lowered by 0.2 to 4.9°C. Although the cooling effect on roofs is significant, shading products did not show noticeable improvement, possibly due to the interference of mist concentration and wind.

The Impact of Equipment Performance on Cooling Misting

Research on outdoor misting systems has provided valuable insights into both indoor and outdoor thermal environments. Cooling sprayers have been widely studied for their ability to improve outdoor thermal comfort and air quality. This research has led to important findings regarding the factors that influence the cooling performance of these systems, emphasizing the importance of optimizing performance by considering both internal and external factors.

Internal Factors

Research on internal factors of the equipment focuses primarily on the control variables related to the nozzles themselves. These include nozzle type, water pressure, nozzle diameter, droplet size, nozzle height, and spray angle. Optimizing these parameters is crucial for maximizing the effectiveness of misting systems in reducing temperatures and enhancing comfort.

External Factors

External factors that affect the performance of misting systems are closely linked to environmental conditions such as air temperature, relative humidity, wind speed, and solar radiation. Understanding how these external conditions influence the cooling effectiveness of misting systems is essential for improving their efficiency and performance in various settings.

By addressing both the internal characteristics of misting systems and external environmental conditions, the operational performance of cooling sprayers can be significantly enhanced. This holistic approach allows for the strategic implementation of misting systems to improve outdoor thermal environments and indirectly enhance indoor thermal conditions, contributing to the creation of more comfortable and healthier living and working spaces.

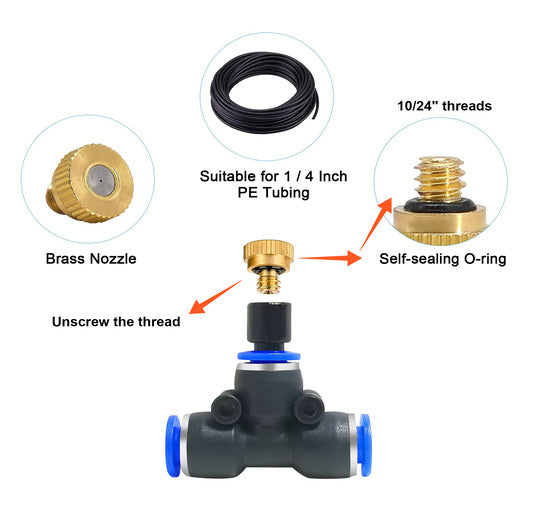

Nozzle Diameter and Nozzle Type

The diameter and type of nozzle are key factors in the design and efficiency of misting cooling systems. They significantly affect the size of water droplets produced, the distribution of mist, and ultimately the overall cooling effect of the system. Understanding these factors helps to optimize misting systems for specific applications, ranging from outdoor cooling to humidification and even agricultural uses.

Nozzle Diameter

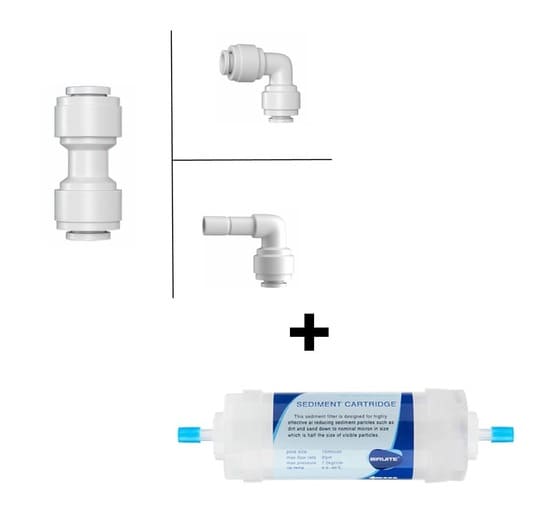

The nozzle diameter affects the speed and size of the water droplets expelled from the nozzle. The smaller the diameter, the finer the mist, the smaller the droplets, the faster they evaporate, and the higher the efficiency, resulting in a better cooling effect. However, the smaller the diameter, the more likely the nozzle will clog if the water is not adequately filtered, requiring more maintenance.

-

Larger Diameter: Typically produces larger droplets that may not evaporate quickly, potentially leaving the misting area wet. These nozzles are better suited for applications where instant evaporation is not required, such as in certain agricultural environments or when the main goal is direct cooling or humidification without concern for residual moisture.

-

Smaller Diameter: Ideal for applications where fast evaporation and significant cooling are needed without wetting surfaces, such as outdoor comfort cooling for people or cooling sensitive equipment.

Nozzle Type

The type of nozzle affects the mist pattern, distribution, and droplet size, which in turn affects the system’s suitability for different environments and applications.

-

Impaction Nozzles: These nozzles force water through small orifices to create fine mist. They are commonly used in cooling systems because they efficiently produce small droplets that evaporate quickly.

-

Ultrasonic Nozzles: Use high-frequency sound waves to generate extremely fine droplets, making them ideal for applications requiring rapid evaporation. These nozzles are highly efficient but more expensive, often used in specialized applications like precise humidity control in greenhouses or laboratories.

-

Atomizing Nozzles: Designed to produce dense fog, these nozzles are suitable for applications requiring high humidity or where maximizing cooling through larger areas of droplets is needed.

-

Rotary Nozzles: These use centrifugal force to expel droplets, creating a fine mist of varying sizes. They are typically used for agricultural cooling and irrigation.

Choosing the right nozzle diameter and type depends on the specific cooling application requirements, including the desired cooling effect, environmental humidity levels, and whether minimal residual moisture is prioritized. Balancing these factors ensures efficient operation of the misting system, providing the necessary cooling or humidification while minimizing water usage and maintenance needs.

Categories of Water Pressure in Misting Systems

-

Low Pressure (Approximately 30 to 50 psi): Low-pressure systems are simpler and more cost-effective, but they produce larger droplets, which may not fully evaporate in hot conditions, potentially leading to wetness.

-

Medium Pressure (Approximately 100 to 250 psi): Medium-pressure systems strike a balance between efficiency and cost, producing finer mist than low-pressure systems but without the high cost of high-pressure systems. They are suitable for residential and light commercial applications.

-

High Pressure (Above 800 psi): High-pressure misting systems offer the highest cooling efficiency because they generate the finest mist, which evaporates quickly. While high-pressure systems provide the best cooling effect, they are also the most expensive, as they require specialized pumps and nozzles to handle the high pressure.

Considerations When Choosing Water Pressure

Selecting the appropriate water pressure for a misting system requires consideration of the specific application needs, including the desired cooling effect, the environment (outdoor vs. indoor, humidity levels), and budget constraints. High-pressure systems are ideal for applications that require maximum cooling and rapid evaporation, such as in dry, hot climates or environments that must maintain the lowest possible humidity. Medium- and low-pressure systems may be more suitable for more humid environments or applications where some moisture residue is acceptable and budget limitations are a concern.

Nozzle water pressure is a critical factor in the operation and effectiveness of a misting cooling system. The pressure at which water passes through the nozzle affects the quality of the mist, the size of the droplets, and the distance the mist can travel before evaporating. Understanding the role of water pressure helps optimize misting systems for specific environmental conditions or applications.

Nozzle water pressure is a critical factor in the operation and effectiveness of a misting cooling system. The pressure at which water passes through the nozzle affects the quality of the mist, the size of the droplets, and the distance the mist can travel before evaporating. Understanding the role of water pressure helps optimize misting systems for specific environmental conditions or applications.